How the Studio’s scientific and engineering competencies are helping clients achieve next-level results.

Part of Studio Volpi’s Technology function, “the Lab” plays a strategic role in delivering world-class support to its clients. Beyond the electronic engineering and mechanical engineering services, as the third arm of the Studio’s Tech Business Unit it is a very concrete high-tech operation that deals with actually building and testing products to see whether they can actually make it to the production line, and eventually to its clients’ final customers. Studio Volpi has gained considerable insight into many an industrial sector and acts as a privileged observation standpoint thanks to its specific, cross-disciplinary know-how.

When testing or building a product or prototype for a client in the Volpi Lab, the Studio brings to the table an educated perspective on many technical aspects; design trends; competitors’ products and visual brand identity; UX latest innovations; User Interface current state-of-the-art; craftsmanship and perceived quality insights; and a wealth of knowledge on materials science. The Lab offers an array of different activities which, alone or combined, lead to the final functional and aesthetic design proposition for the clients’ products and to the construction of truer-than-life fully functioning units.

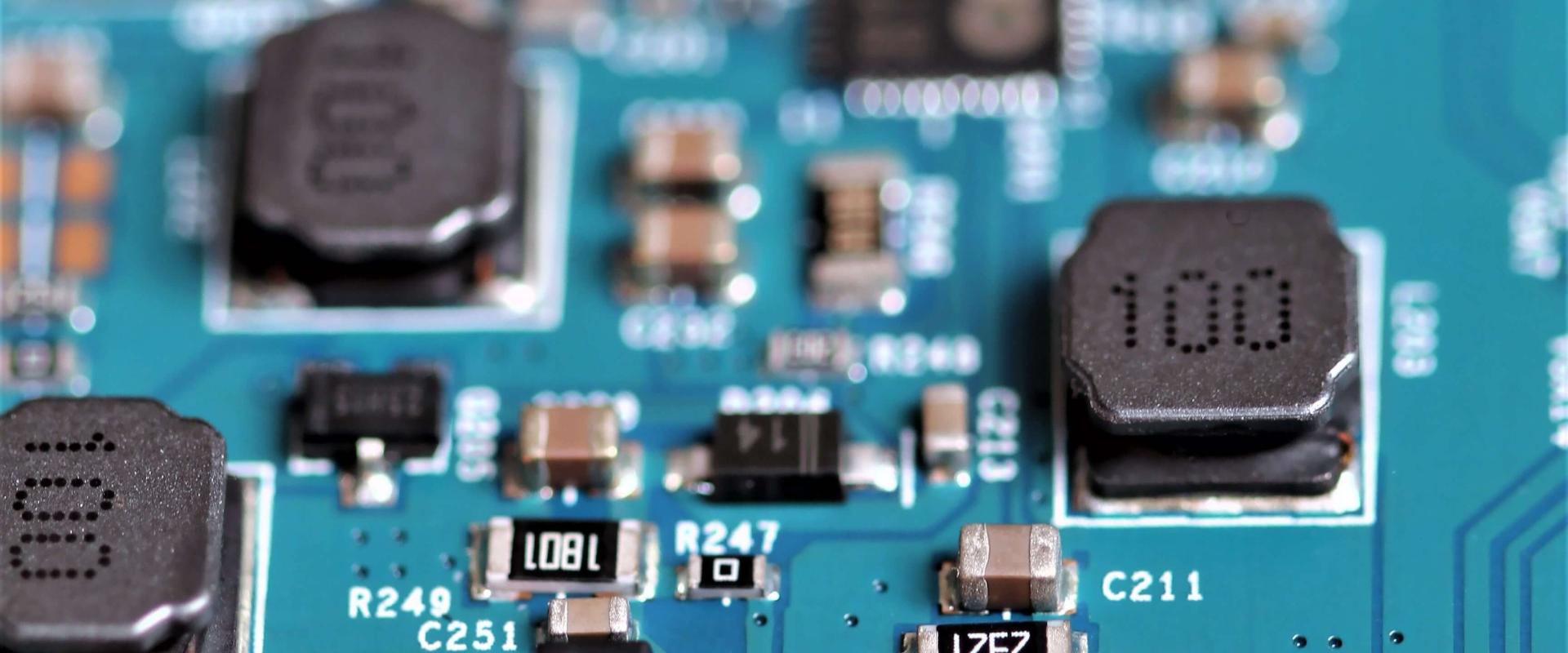

To build it better, tear it apart first

Tech tear-down is part of the activities of the Lab. By disassembling reference products, those of competitors for instance, Lab engineers can observe and categorise core functional components in order to understand the underlying technologies. This also helps gain a precise idea of costs involved and set performance parameters and acceptance criteria for the new product being developed. This leads to the creation of meaningful, sharp technical specs and the precise definition of features with regards to connectivity, functionality and interfaces. This phase is also important since by comparing different possible technological approaches, the best corresponding components can be identified. Also, DOE (Design of Experiment) is another significant outcome of Tech Tear Down, with the creation of test benches, validation protocols and UI “black boxes” for testing.

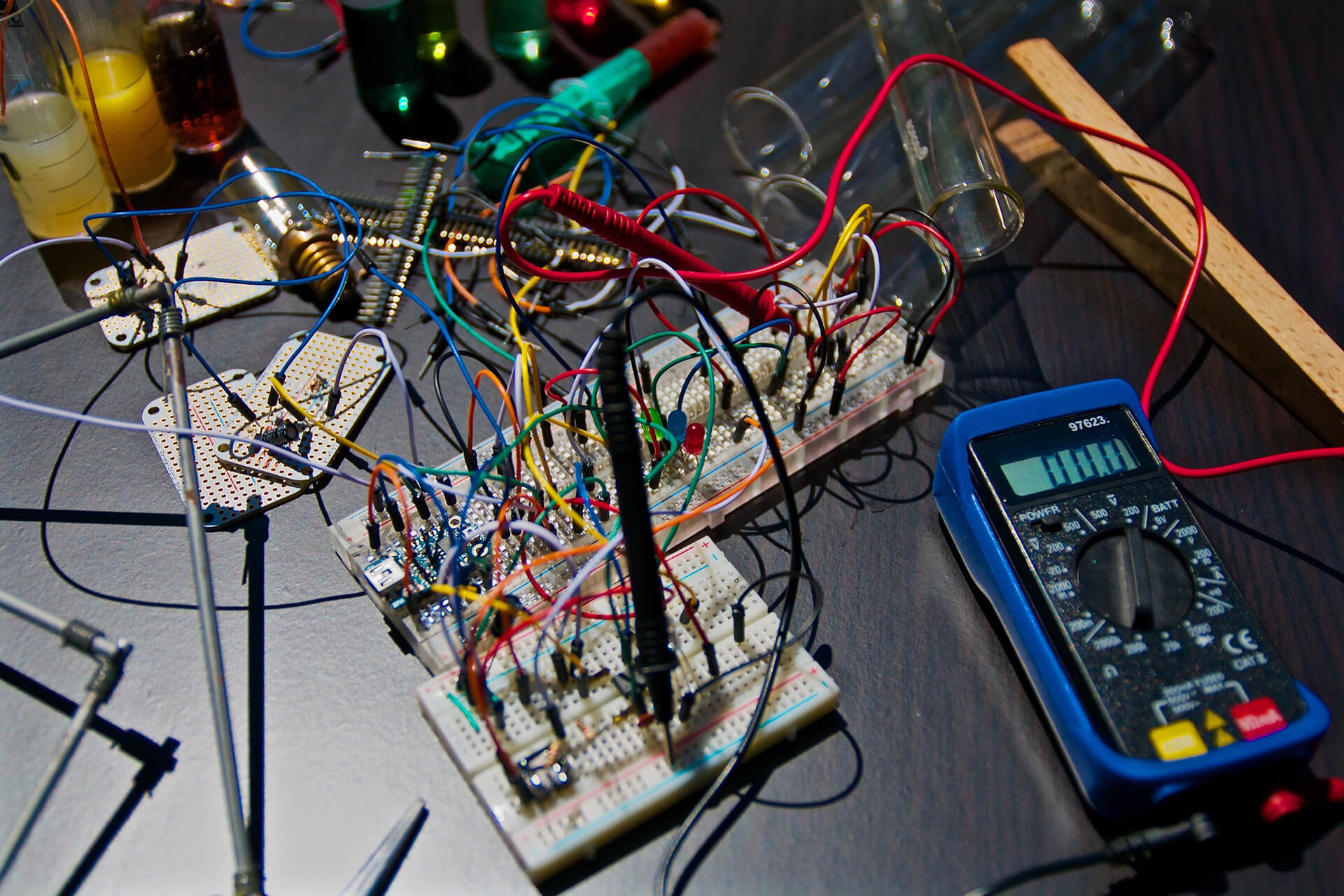

Putting ideas to the test

Proof of Concept is another crucial activity performed at the Lab. It will tell whether an idea is technically feasible, and what the critical issues might be in addition to how the product might be used and how it would work like. The goal of the Studio is to consistently meet or exceed field application specifications. Thanks to its multidisciplinary approach, issues and criticalities can be rapidly addressed and solutions found through multiple design iterations according to the principle “do-test-analyze-repeat” until target specs are reached.

How well does it work?

Here primary functionalities are evaluated with the help of advanced prototypes. This involves the creation of specific procedures also to assess product behaviour and user experience, a fundamental part of the successful design of any product. Several prototype concepts can be put to the test to help determine the best and final design.

How good does it look?

Functional and aesthetic prototyping allows for the testing of working prototypes under as-real-as-possible end-user conditions, typically at events and exhibitions. Collecting feedback from a wide range of final users helps validate final aesthetics and usability of the product, while identifying and addressing potential criticalities before costly investments in large scale production tooling. Likewise, production grade materials can also be validated through a realistic simulation of mechanical functions, and of chemical and thermal stress. This kind of testing further proves the suitability of the form and of complex assemblies’ components, and ensures the accuracy of pre-assembled parts.

Protecting ideas and technologies

Studio Volpi’s extensive know how and expertise in a variety of fields often leads, within the activities of the Lab, to the development of new, innovative technologies, and results in a number of patent applications. That same expertise is extremely valuable when it comes to assist in the definition of product specifications and the production of precise and effective briefs.

The miniature factory

The Lab also has the capacity to actually build products in small batches. This limited-series controlled manufacturing capability is extremely useful in field-test campaigns and as an alternative to full-scale industrial process. In effect, in many cases field-testing reliable prototypes that are identical to their industrialised versions is essential prior to initiating mass production. Inversely, where production volumes are limited and don’t justify investments into a fully blown industrial production setup, market-grade small batch production represents a valid solution.

The Volpi Lab may well be Studio Volpi’s best kept secret, but a formidable tool that combines craftsmanship, engineering and design excellence with market and industry insights on current and future trends. A true asset for companies wanting to perfect their products and a further proof of the unique proposition of Studio Volpi.

-

-

-

Prospettive Mar 30, 2020

KITCHEN 4.0: HOW DIGITALIZATION IS CHANGING THE RULES

Technological updating and the integration of an interconnected soul are turning modern professional kitchens into a perfect example of the 4.0 industry, where the product and its super digital powers become a tool to improve working conditions, enhance productivity, monitor the processes to achieve better results and create new business models